Product

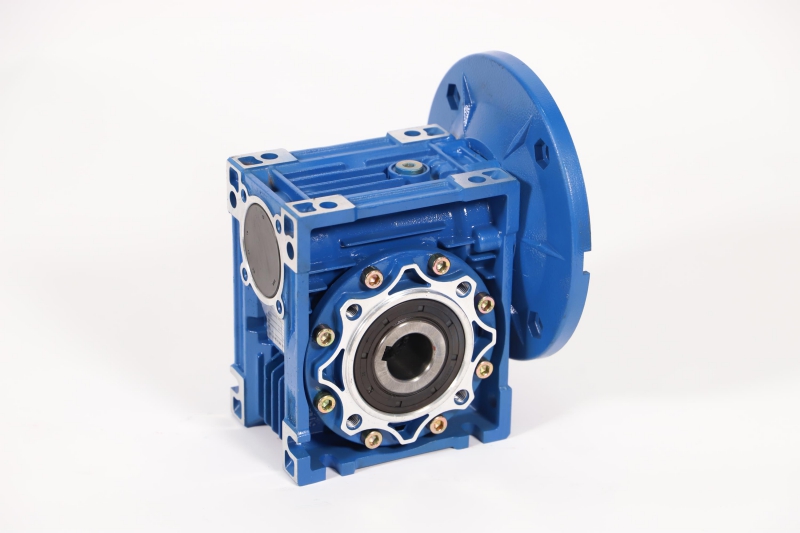

Categories Worm Gear Reducer

Model RV Series

Type Worm Gear Speed Reducer / Gearbox / Reductor

Model WMRV 25/30/40/50/63/75/90/110/130/150/185

Ratio 7.5/10/15/20/25/30/40/50/60/80/100

Color Blue(RAL5010) / Silver Gray(K9149) or Customized Color

Packing Carton, Honey Comb Carton, Wooden Case with Wooden Pallet

Usage Industrial Machine, Food Stuff, Ceramics, Chemical, Packing, Dyeing, Wood Working, Glass, etc.

Flange IEC standard flange or customized dimensions

Technical features:

| Housing Material | Aluminum&Cast iron |

| Gearing Arrangement | Worm and worm wheel |

| Size | 11 sizes(WMRV25~WMRV185) |

| Power | 0.06~22 KW |

| Nominal torque | ≤2548 N.m |

| Ratio | 11 choices(5~100) |

Advantages:

- Viton oil seal High temperature resistant Anti-oxidation Less oil leakage

- Unique Housing Design

Precision measurement for housing and parts

Semi-automatic assembly line

100% running test

100% Air tightness test

MITSUBUSHI Hobbing machine

LG-MAZAK vertical machining center

DMG Mori vertical/horizontal machining center.

Features of Worm Reducer /Gearbox

1.Common mounting dimensions.

2.Aluminum and cast iron housing.

3.Worm and worm wheel transmission.

4.Compact structure and light-weight.

5.Wide range of accessories.

Benefits of Worm Gearbox / Reducer

1.Unique housing design will distinguish you from other competitors.

2.Multiple choice for oil seal.

3.The dimensions can be customized according to customer’s requirements.

Categories Hypoid Gear Reducer

Model WAH Series

FOB Port Ningbo,Shanghai

Features

1.Hypoid gear transmission.

2.Aluminum housing.

3.Common mounting dimensions.

4.Wide range of accessories.

Benefits

1.Higher performance and reliability.

2.Long service life.

3.Low temperature rise.

4.Unique housing design.

| Housing Material | Aluminum |

| Gearing Arrangement | hypoid gear |

| Size | 4 sizes(WAH50~WAH90) |

| Power | 0.12~4 KW |

| Nominal torque | ≤350 N.m |

| Ratio | 7.5~300 |

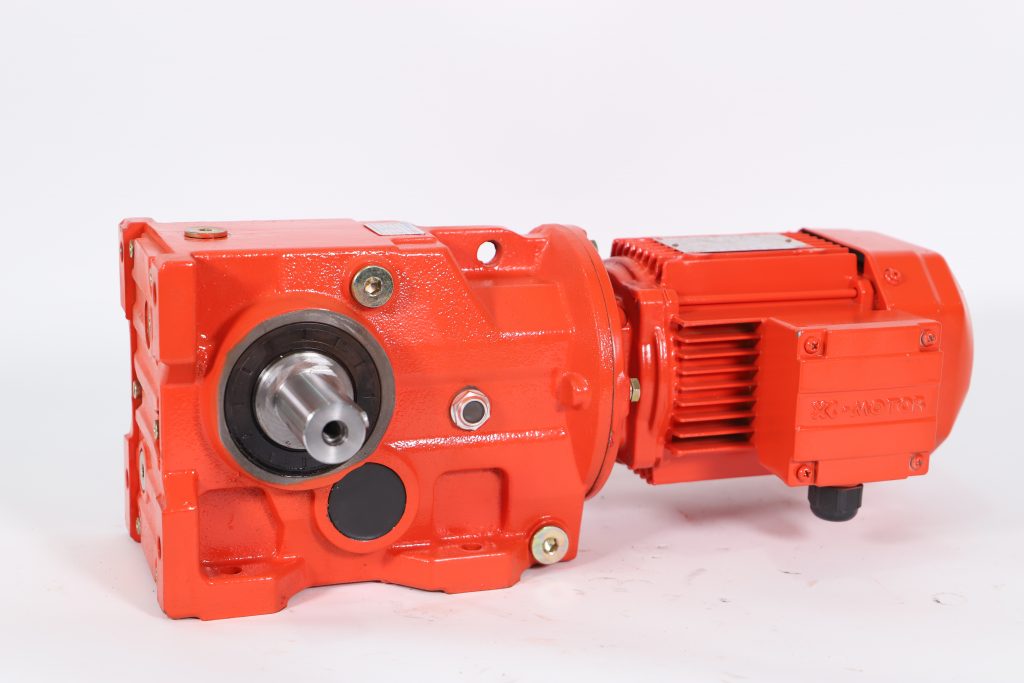

Categories Helical Gear Reducer

Model WR Series

FOB Port Ningbo,Shanghai

Type WR series Inline helical gear reducer / gearbox

Model WR17/27/37/47/57/67/77/87/97/107/137/147/167

Mounting type Flange, hollow shaft, solid shaft

Efficiency 94%-98%

Housing Material HT250 cast iron

Technical features

| Size | WR17-WR167 |

| Ratio | 3.41-289.74 |

| Power | 0.12-160KW |

Strict production process

High precision level: grade 6

Semi-automatic assembly line

100% running test

Noisy level control

Vibration test

MITSUBUSHI Hobbing machine

LG-MAZAK vertical machining center

DMG Mori vertical/horizontal machining center.

Features of inline helical gearbox

1.Strong cast iron housing.

2.Wide range of sizes.

3.High carrying ability.

4.High efficiency.

5.Univeral mounting.

Benefits of inline helical gearbox

1.Unique housing design.

2.Long service life.

3.Low temperature rise.

4.Unique housing design.

WS helical worm gear reducer

Features

1.Strong cast iron housing.

2.Wide range of sizes.

3.High carrying ability.

4.High efficiency.

5.Univeral mounting.

Benefits

1.Unique housing design.

2.Long service life.

3.Low temperature rise.

4.Unique housing design.

Technical features:

| Size | WS37-WS97 |

| Ratio | 6.8-288 |

| Power | 0.12-30KW |

Gears

Products type: cylindrical gears,bevel gears,worm gears, sprocket and pinions ETC,

Material: alloy steel,

Heat treatment: carburizating, quenching.

Surface Treatment: shot blast

Module: 0.5M-6M.

Accuracy class: GB grade 3-7.

Highlight: We can do high precision gears with accuracy.

Application: agricultural and gardening machinery

Design Support: PDF,Auto CAD, Solidwork

Packing: Carton;wood case;pallet or container

Process:

Drawing or sample from customers→blanking→forging→rough machining→fine machining→quenching→fine machining→ inspection →packing

We provide cylindrical gears, bevel gears,worm gears and worm shafts for different markets and applications

CNC machining center system: OKUMA system and FANUC system, Mitsubishi system, Heidehan, Rhodes and so on

We have a CNC machining center system, equipped with skilled technical operators and machine maintenance personnel, in line with The Times and international development trends, greatly improve the processing efficiency and processing accuracy, to provide you with high-quality and low-cost machining technology and parts.

Processing process: automatically drilling, countersinking, reaming, boring, tapping, milling and so on for each machining surface of the workpiece

There are many kinds of CNC, CNC lathes, vertical CNC milling machine, horizontal CNC milling machine, CNC wire cutting machine and machining center……

Horizontal Machining Center,CNC Wire-cutting Machines

We can provide professional surface treatment production line, surface white galvanized or color galvanized production line, surface electrophoretic coating production line

Surface Treatment: Spray Painting, Spray, anti-rust oil, galvanized, polishing, shot blast, black oxidation

Welding: electric welding, spot welding, argon arc welding, gas shielded welding.

Forging – hot forging, cold forging, cold heading, roll forging, radial forging and extrusion

Casting – Sand Casting, metal Casting, Investment Casting,

Centrifugal casting

Annealing, normalizing, quenching and tempering, tempering, carburizing

Injection molding parts: Professional injection molding plant, professional operator skilled operation of specific injection molding machine to provide you with high-quality injection molding parts. We pay attention to the practical experience and the objective environment (such as ambient temperature, humidity, air cleanliness) with the seasonal differences, these objective and subjective conditions together determine the market advantage of our injection molding products. The production of injection parts is generally made by molding, transfer molding, and injection molding.

Forging – hot forging, cold forging, cold heading, roll forging, radial forging and extrusion

Casting – Sand Casting, metal Casting, Investment Casting,

Centrifugal casting

Equipment:

Forging equipment includes forming forging hammer, mechanical press, hydraulic press, screw press and flat forging machine, as well as forging operators, uncoiling machine, straightening machine, shearing machine, and other auxiliary equipment

Casting Equipment

1.Medium frequency furnace 2.Resin sand production line

3.Molding machine 4.Rotor sand mixer

5.Sand blasting machine 6.Automatic core shooting machine

7.Shell shooting machine 8.3-5t crane

Showing the single result